PRODUCT CENTER

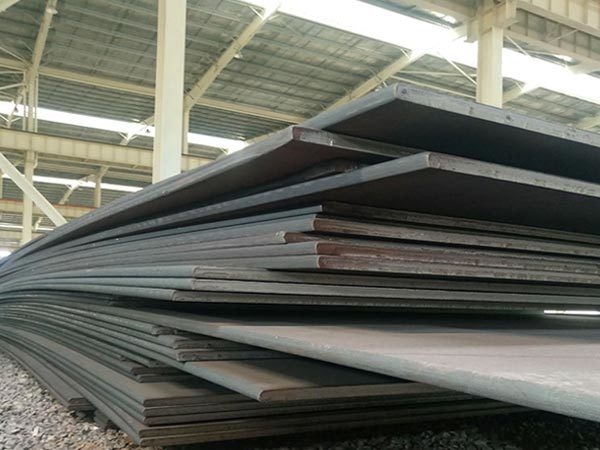

We attach great importance to product quality and have adopted strict quality control measures. From the arrival of raw materials to the delivery of products, each link is strictly inspected and monitored to ensure that product quality meets national standards and customer requirements.

ASTM A283 steel coil is low carbon structural steel that is formable and strong. It shows excellent weldability and machining capability, making it ideal for use in industrial and commercial structures. There are four grades: A, B, C, and D.

A106 Carbon Steel Seamless Pipe

ASTM A106 seamless steel pipe could transport fluids or gasses at high temperature and pressure levels, with 3 grades A, B, C, most common used ASTM A106 Grade B is widely used in the projects of oil and gas refineries, power plants, petrochemical plants, boilers.

ASTM A36 steel plate is one of the most common grades of steel used in structural applications. This mild carbon steel grade contains chemical alloys that give it properties such as machinability, ductility, and strength that are ideal for use in constructing a variety of structures.

ASTM A36 steel bar is one of the most common grades of steel used in structural applications. This mild carbon steel grade contains chemical alloys that give it properties such as machinability, ductility, and strength that are ideal for use in constructing a variety of structures.

Grade 304 is the most commonly used stainless steel. It is an austenitic, corrosion-resistant steel with excellent strength, toughness, fabrication characteristics and weldability. The low carbon version, 304L, may be required for full corrosion resistance when thicker sections are welded.

ASTM A53 seamless and welded steel pipe is a general, all-purpose pipe. Designed for coiling, bending, and flanging, A53 carbon steel pipe is suitable for welding. The grades denote certain chemical and mechanical properties and should be noted in the selection.

Type 316 stainless steel is an austenitic grade with added molybdenum. The alloy offers improved corrosion resistance when compared with Type 304, particularly in chloride environments.

ASTM A335 is a common material for American standard alloy steel seamless pipes. It's material contains alloy elements such as Cr, Ni, and Mo, which can improve the high-temperature and high-pressure resistance, corrosion resistance, and mechanical properties of steel pipes.

ASTM A36 steel coil is one of the most common grades of steel used in structural applications. This mild carbon steel grade contains chemical alloys that give it properties such as machinability, ductility, and strength that are ideal for use in constructing a variety of structures.

Type 316L stainless steel in a molybdenum bearing austenitic. It is more resistant to general corrosion and pitting than conventional nickel chromium stainless steels such as 302-304. It has the following characteristics:Higher creep resistance,Excellent formability,Rupture and tensile strength at high temperatures,Corrosion and pitting resistance.

A285 Carbon Steel Pressure Coil

ASTM A285 standard is for carbon steel, low and intermediate tensile strength steel coils intended for fusion-welded pressure vessels. The steel coil under ASTM A285 ranges in three grades, A, B and C, most common use is ASTM A285 Grade C coils.

304L stainless Steels lower carbon content helps minimize/eliminate carbide precipitation during the welding process. This allows 304L stainless steel to be used in the “as-welded” state, even in severely corrosive environments.

1050 Aluminum is a commercially pure aluminum alloy that is known for its excellent corrosion resistance, high thermal conductivity, and good workability. It is commonly used in various industries such as electronics, chemical equipment, and signage.

1060 aluminum is commonly used in the electrical and chemical industries, on account of having high electrical conductivity, corrosion resistance, and workability. 1060 aluminum has low mechanical strength compared to more significantly alloyed metals. It can be strengthened by cold working, but not by heat treatment.

Aluminium 1070 alloy is a wrought alloy type with good corrosion resistance. It is an excellent brazing alloy. Aluminium 1070 alloy is chiefly used in the following areas:General industrial components,Building and construction,Transport,Electrical material,PS plates,Strips for ornaments,Communication cables,Refrigerator and freezer cabinets,For joining two pieces of aluminium / aluminum.

Galvanized steel sheet is standard steel that is coated in zinc to provide enhanced corrosion resistance. The galvanized protective coating protects the iron steel substrate from corrosion due to moisture, saturated environmental conditions, or ambient humidity.

904L is a stainless steel alloy that displays high resistance to corrosion, particularly against acidic environments. Therefore, 904L isapproved for use in acid production and concentration, along with the transport of such substances.</br> With excellent weldability and formability 904L also maintain non- magnetic state in all conditions. </br> 904L provides excellent toughness , even down to cryogenic temperatures with its austenitic structure.

ASTM A572 steel bar is a popular grade of high-strength low-alloy (HSLA) steel that is typically used in structural applications. A572 steel contains chemical alloys that enhance the material’s hardness and ability to bear weight. There are five different grades of A572 steel plate: Grade 42, Grade 50, Grade 55, Grade 60 and Grade 65.

Carbon Steel Reinforcing Bar (Rebar)

Stainless Steel Wire refers to a type of wire made from chromium-containing alloys with excellent corrosion resistance, strength, and weldability, commonly used in various applications in the nursing and health professions.

Carbon steel wire is one of the most versatile materials available on the market today. It has a wide range of uses, from construction to manufacturing, and everything in between. Let’s take a a closer look at some of the most common uses for carbon steel wire.

PARTNER

SHANDONG ZHONGYI STEEL CO., LTD.

Zhongyi Steel is a steel manufacturer and supplier integrating industry and trade. It has its own factory department, domestic Trade Department and International Trade Department. With Jinan Iron and Steel, Laiwu Iron and Steel, Handan Iron and Steel, Anyang Iron and HBIS, BaoSteel and many other international steel established long-term cooperative relations.We use advanced production processes and technologies, such as modern continuous casting, rolling, heat treatment and other equipment and technical means. These advanced processes and technologies can ensure the stability and excellent performance of steel. We attach great importance to product quality and have adopted strict quality control measures.

SEE MORE+Production Experience

Active Employees

Floor Area

Export Country

CUSTOMER VISIT

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

Customer visit

NEWS CENTER

Our products are sold all over the country and exported to more than 100 countries around the world, such as the European Union, the United States, Australia, Southeast Asia, and the Middle East, etc.